Advancing a net zero future

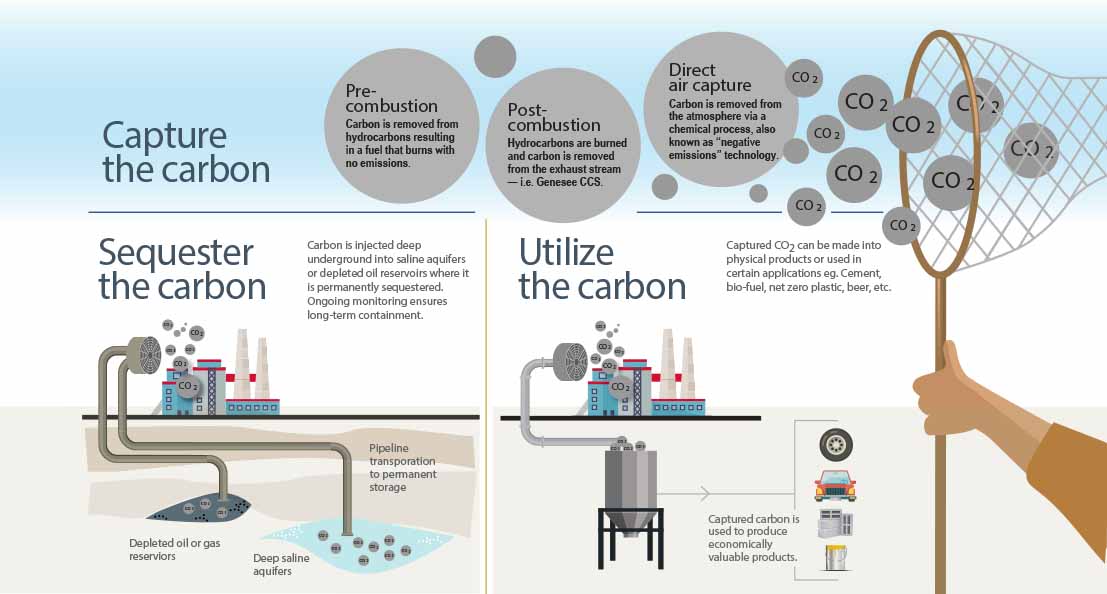

We’re committed to doing our part in the transition to a net zero energy future. That’s why we’re proud to support and advance the commercialization of carbon capture, utilization and sequestration (CCUS) technology and plan to integrate direct air capture (DAC) into our portfolio of decarbonization technologies to further reduce emissions.

We recognize CCUS as an integral part of the long-term solution to tackle climate change globally and enable zero or near-zero emissions from natural gas generation. When combined with the integration of renewables, CCUS will ensure the ongoing affordability and reliability of our power systems while critically reducing emissions. The addition of DAC technology further supports our decarbonization goals by offering the potential to physically offset emissions from our portfolio that are not technically or economically feasible to eliminate at source.

To support our efforts to advance the development and commercialization of CCUS technology, we’re participating in the Carbon Capture Coalition and Canadian Carbon Capture Collaborative.

Genesee CCS Project

As part of our approach to decarbonization, we’re prioritizing physical emissions reductions from our facilities to support our long-term resiliency. As a result, we’re developing plans to apply carbon capture and sequestration (CCS) technology at Genesee 1 and 2. When operational, this project is anticipated to capture 95% of the CO2 emitted from the repowered units and deliver approximately 3 million tonnes of annual CO2 reductions. In June 2022, we announced that we partnered with Mitsubishi Heavy Industries Group and Kiewit Energy Group on a front-end engineering and design (FEED) study to determine the next stage of engineering and design for the project. In July 2022, the project was awarded Carbon Capture Kickstart funding from Emissions Reduction Alberta. In addition to this project, we announced a collaboration with Enbridge on the development of an open access carbon hub in the Wabamun area, near our Genesee facility. In December 2022 , we announced that our Genesee CCS project received Limited Notice to Proceed approval from our Board of Directors. This decision moves the project into the next stage of final due diligence and commercial/financing assessment; a final investment decision will be announced when this is complete.

Direct Air Capture

We believe a combination of technologies will be necessary to achieve our goal of being net zero by 2045. DAC is a promising technology that will support our decarbonization efforts by physically reducing emissions across our portfolio. DAC complements the other technologies in our portfolio and offers the potential to reduce emissions from our facilities that may otherwise have limited opportunities for decarbonization due to technical or economic limitations.

Genesee Carbon Conversion Centre (GC3)

Capital Power is proceeding with plans to build the world’s largest commercial scale production facility of carbon nanotubes (CNTs) at our Genesee Generating Station. The project received Alberta Utilities Commission approval on June 18, 2021 and is also a recipient of Emissions Reduction Alberta funding through their Shovel-Ready Challenge. The design phase of GC3 is underway. The project will have an initial production capacity of 2,500 tonnes of CNTs per year and once completed will be capable of producing up to 7,500 tonnes annually. GC3 will deploy C2CNT technology – a carbon utilization solution that transforms emissions into high quality carbon nanotubes. Capital Power is a 40% equity owner in C2CNT LLC.

Hydrogen

In 2023, we were selected as recipients of Ontario Energy’s Hydrogen Innovation Fund, which paves the way for the production of reliable, affordable and clean electricity from hydrogen to help power the province’s growth.

At our Goreway Power Station, East Windsor Cogeneration Centre, and York Energy Centre, we’re exploring hydrogen blending using various mixes of hydrogen (from 5% to 15%). Engineering studies will be conducted at each site to evaluate the impacts on the natural gas turbine’s performance, maintenance, operability, emissions, and safety considerations, as well as how hydrogen could be procured, transported, and stored.

At Kingsbridge, we’re exploring the economic and technical feasibility of creating green hydrogen from wind and storing it underground in depleted gas reservoirs.