Powering a lower-carbon energy future

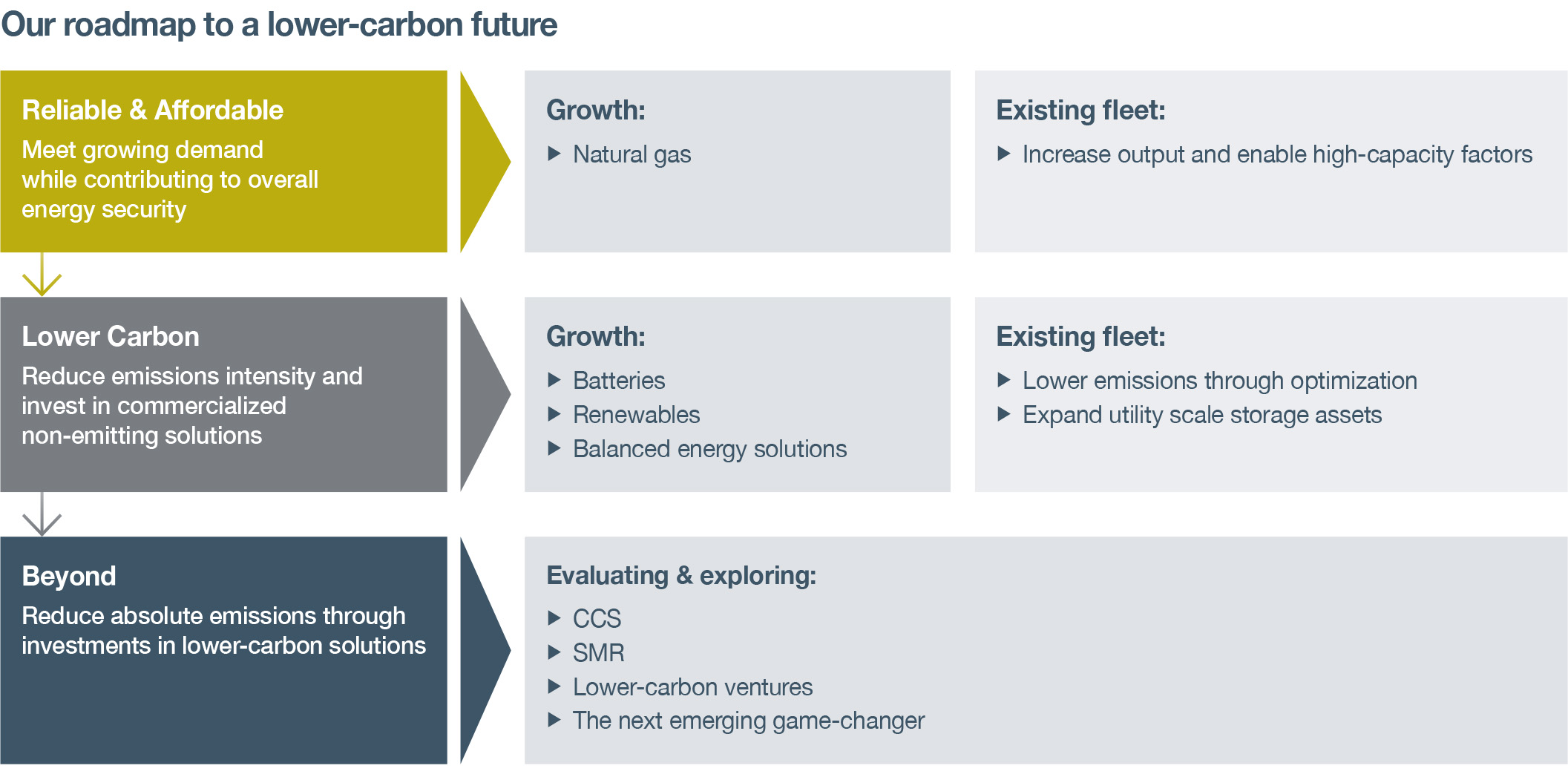

We are working to meet the growing demand for energy while tackling the urgent challenge of climate change by delivering grid-critical capacity, pursuing lower-carbon power solutions, and making strategic investments to optimize our existing power generation assets.

We have the responsibility and expertise to help lead North America’s transition to a lower-carbon economy while providing our customers and communities with access to reliable and affordable power during this time of energy expansion. As we prioritize delivering balanced energy solutions for our customers, our investment decisions are guided by a target to allocate 30% of our growth capital over the next 5 years towards renewables and other lower-carbon solutions.

Our strategy is working to deliver more energy while scaling up lower-carbon solutions and reducing our emissions intensity – we will continue to transparently report our progress every year.

We’re proud to support peregrine falcon conservation

at our Genesee Generating Station in Alberta.

Learn more